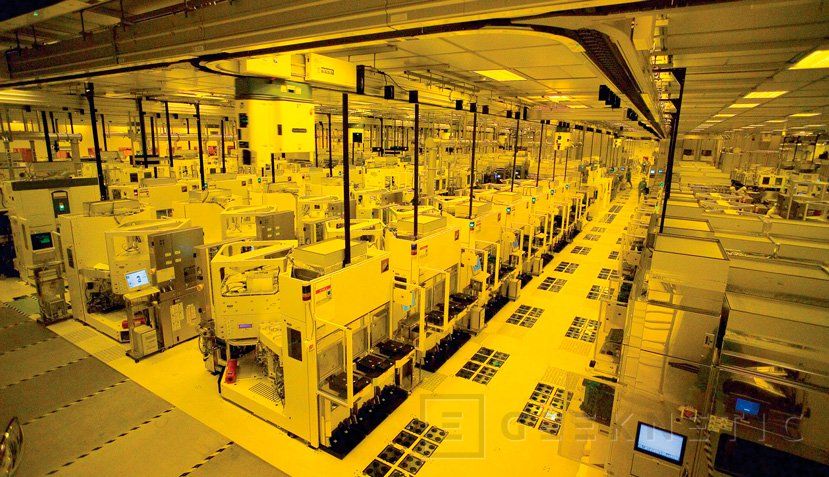

During the company’s annual technology symposium, the manufacturer TSMC presented the planned features of its 3nm (N3) process node, which will go into trial production in 2021.

TSMC explained its 3nm process technology, which will enter into production in 2021

Prior to 3nm, TSMC plans to release a 5nm+ process node (N5P) and a 4nm node (4N), both of which will be an improved version of 5nm that has already entered mass production. 5nm+ will provide a frequency increase of 5% over 5nm or a 10% reduction in power consumption. 4nm will offer users additional layers of EUV to reduce the number of layers.

At 5nm, TSMC claims to deliver 15% more power than the 7nm at the same power consumption or 30% less power at the same power. In addition, the density above 7 nm is increased by 1.8 times. At 3nm, TSMC plans to reduce power by 25-30% at the same power as 5nm or increase power by 10-15% at the same power consumption with a 1.7-fold increase in silicon density.

Apple has seen strong demand for the new 5nm process for its upcoming A14 and A14X Bionic chips and MacBook processors. It is currently estimated that the company has ordered between 40,000 and 45,000 5nm processing power in the first quarter of 2020. Qualcomm is also entering the 5nm chip market with its next-generation flagship Snapdragon 875 processor. Similarly, MediaTek plans to introduce its next-generation Dimensity chip, which is scheduled to go into production in the fourth quarter of 2020.

When comparing 3nm to 7nm, the 3nm node should offer customers a 3.06-times increase in silicon density, up to 51% less power consumption for the same power, or up to 32.25% more frequency for the same power consumption as 7nm. 3nm is expected to enter high-risk production in 2021 and mass production in the second half of 2022.