Fujitsu launched “FUJITSU Manufacturing Industry Solution COLMINA Service SMT-Assist (SMT-Assist)” for customers of electronic parts/devices / electronic circuit manufacturing industry.

What is SMT-Assist?

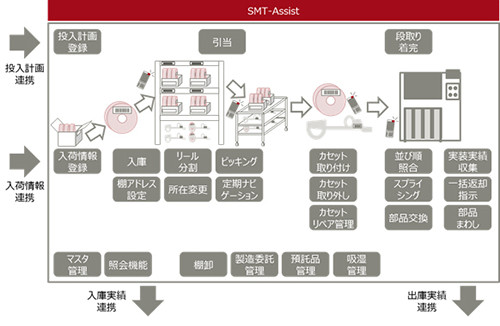

“SMT-Assist” is an SMT line that solders electronic components on printed circuit boards at Shimane Fujitsu, which manufactures notebook PCs of the company, streamlined the setup work of reel-shaped electronic components mounted on the mounter A solution that utilizes the mechanism to realize productivity improvement of about 30%.

With the diversification of customer needs, there is a demand for change from mass production to manufacturing that realizes a flexible production method, but in the case of a business owner holding a mounter, when producing small lot, Reduction of production efficiency, such as more setup change work, is a problem.

Are we closer to the universal translator?

By doing inventory management comprehensively and appropriately, it suppresses excess and deficiency of reel inventory and realizes cost reduction.

Also, by classifying the setup change work of the reel parts for each role of the worker. Also, that includes incidental work such as cleaning of equipment and visual inspection. In addition, it works by displaying it on the handy terminal owned by the operator as a work instruction.

USB Type C: Advantages and Disadvantages of Fashion

Furthermore, by monitoring the remaining amount of individual reel parts attached to the counter and the actual usage of the cassette to be mounted. Also, it is possible to predict and prevent the stop of the equipment. Regarding reel injection plans, it is possible to calculate the allocation of reel inventory. So, that the setup changes time will be the smallest. And that works to improve productivity by about 30% by improving equipment availability.