On 16th March, Rohm invented a 3-axis acceleration sensor BW 9577 for earthquake detection chip that distinguishes between a real earthquake vibration of artificial vibrations.

The new sensor detects the vibration exactly in case of an earthquake by using a distribution board. It operates with a high-precision seismic sensor module “BW 9577”. That is capable of discriminating between earthquakes and artificial vibrations. By judging the seismic level with the earthquake waves that have occurred.

BW 9577 seismic sensor module technology?

This time, the company develops a proprietary algorithm focusing on the SI value. By taking a through analysis of measured data, they have succeeded in realizing high-precision earthquake Digital Signal Processing Of Acceleration Data.

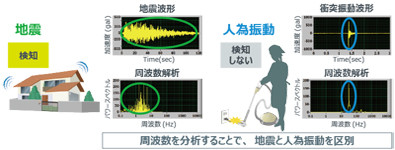

With the optimization Of Calculation Parameters And Calculation Sequence. Also, Artificial Vibration Caused By Human Daily Life. Such As Cleaning Is Known As A Factor Of False Detection. So it incorporates false detection prevention function. That is developed by analyzing each vibration waveform of such an artificial vibration.

With these algorithms such occurrences of vibrations are distinguish. Whether they are the true seismic activity vibrations or the artificial vibration wave forms. And then it outputs the accurate signal if and only if there is a true occurrence of an earthquake.

In addition, this product also adopts the company’s group product MEMS 3-axis acceleration sensor. This uses the Lapis Semiconductor’s CMOS 32bit microcomputer. That is special for sensor control. And by using optimal designing it has a dimension of 9.3 mm × 9.8 mm × 2.1 mm. And it is surely getting advantage with the less space requirement in the design of products.

The product will start shipping samples from August 2017 and will start mass production from December 2017.

The appearance of seismic sensor module “BW 9577” and the image while distinguishing between earthquake and artificial vibration