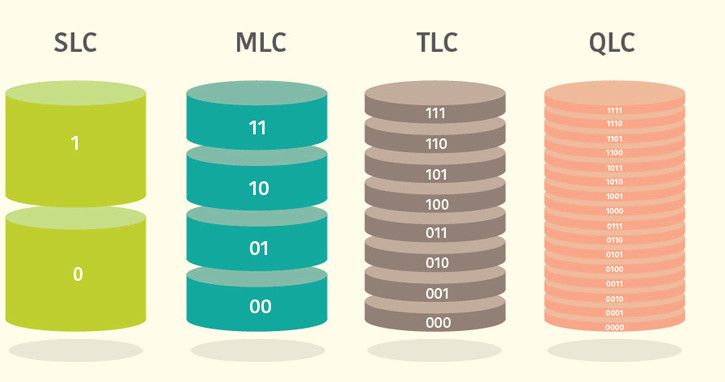

Unsurprisingly optimistic forecasts for the SSD market. DigiTimes Service claims, citing its well-informed sources, that memory chip manufacturers have a big problem with the procurement of 3D NAND QLC chips. Operators are struggling to improve and want to improve the TLC production process, which has been somewhat neglected due to high demand. 3D QLC is the latest ready-to-use NAND storage technology with promises of higher density than 3D TLC, making prices per GB even lower. However, as with all wafer-based PC components, yields are an extremely important part of this process. Cost reductions can only be achieved if manufacturing allows a certain percentage of a wafer to be fully functional and free of defects that affect its functionality or performance.

3D QLC memories are currently causing manufacturers headaches, with very low wafer performance of about 50% or less.

According to the DigiTimes website, 3D TLC performance did not start until the beginning of the year, when companies launched their first 3D QLC designs. And yes, it took NAFTA longer than expected to achieve respectable yields per wafer, and it looks like the QLC memory will take even longer:

It was known that manufacturers like Intel and Micron had a yield of less than 50% with 3D QLC, but it seems that all manufacturers face this disadvantage, and we’re not talking about a few manufacturers (Samsung Electronics, SK Hynix, Toshiba/Western Digital and Micron Technology/Intel).

As a result, prices are likely to tend higher in early 2019, as forecast production volumes do not meet demand, and 3D TLC offerings will face higher demand as QLC storage becomes scarce.

Leave a Reply